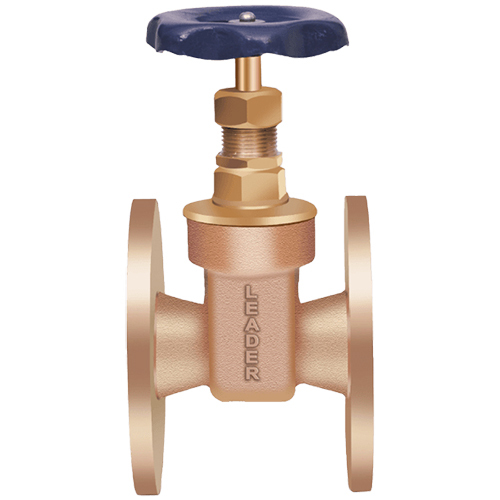

Screwed Ball Valve

Product Details:

- Product Type Screwed Ball Valve

- Size Standard

- Structure Ball

- Color White

- Usage Industrial

- Media Water

- Click to View more

Screwed Ball Valve Price And Quantity

- 50 Piece

- 100 INR/Piece

Screwed Ball Valve Product Specifications

- Industrial

- Ball

- Water

- Screwed Ball Valve

- Standard

- White

Screwed Ball Valve Trade Information

- Cash in Advance (CID)

- 100000 Piece Per Month

- 2 Days

- All India

Product Description

There is a bore or tunnel running through the ball inside the valve. The bore lines up with the pipe when the valve is open, allowing fluid to pass through. The ball rotates 90 degrees when the valve is closed, making the bore perpendicular to the pipe and preventing fluid flow.

Plumbing and industrial applications that call for a tight shut-off frequently use screwed ball valves. They are renowned for their dependability, toughness, and simplicity of use. Installation and maintenance of the valve are made rather straightforward by the screw threads on the valve body.

The suitable valve must be chosen for your individual application in order to ensure proper operation and system compatibility. Screwed ball valves are available in a variety of sizes, materials, and pressure ratings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Industrial Valves' category

GST : 19ALVPP1192L1Z7

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free