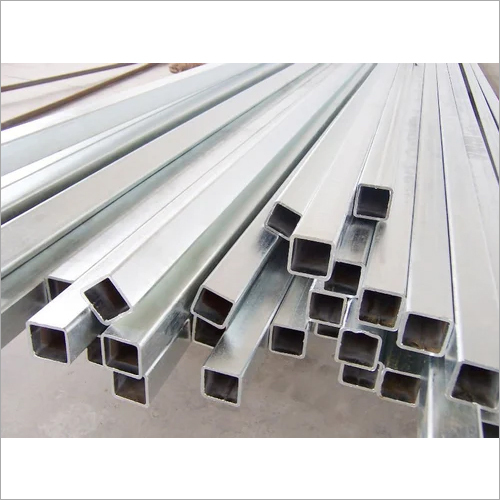

Seamless Pipe

Product Details:

- Usage Industrial

- Product Type Seamless Pipe

- Material Mild Steel

- Shape Round

- Color Silver

- Click to View more

Seamless Pipe Price And Quantity

- 58000 INR/Ton

- 5 Ton

Seamless Pipe Product Specifications

- Seamless Pipe

- Silver

- Round

- Mild Steel

- Industrial

Seamless Pipe Trade Information

- 100000 Ton Per Month

- 2 Days

- All India

Product Description

A form of pipe known as a seamless pipe is one that has no welded seams or joints throughout the manufacturing process. It is created by drilling a hole through a solid cylindrical billet or ingot, which then undergoes additional processing using a variety of hot or cold working processes to provide the required dimensions, surface finish, and mechanical qualities.

The following are some crucial traits and qualities of seamless pipes:

- Manufacturing Method: A hot or cold working procedure is used to create seamless pipes. In order to create hot-rolled seamless pipes, a solid billet or ingot must first be heated before being punctured to create a hollow tube. Contrarily, to produce cold-drawn seamless pipes, a tube is pulled through a succession of dies to reduce its diameter and produce the desired shape and size.

- Seamless Structure: The lack of seams or welds in seamless pipes offers a number of benefits. It guarantees structural consistency, enhancing strength and dependability. Applications requiring high pressure, temperature resistance, and improved corrosion resistance are particularly well suited for seamless pipes.

- Wide Variety of Materials: Carbon steel, stainless steel, alloy steel, and non-ferrous metals are just a few of the materials that can be used to create seamless pipes. The selection of the material is based on the needs of the particular application, such as temperature, pressure, corrosiveness, and mechanical qualities.

- Size and Dimensional Range: Seamless pipes come in a variety of sizes and dimensions, from those with tiny to those with enormous diameters. They can be produced with exact tolerances and dimensional correctness to satisfy the demands of certain projects.

- Versatility of Use: Seamless pipes are widely used in a variety of industries, including the oil and gas, petrochemical, power generation, automotive, and construction. They are employed in a variety of systems, such as pipelines, heat exchangers, boilers, machinery, and structural elements, for the transportation of fluids, gases, and solids.

- Enhanced Performance: Seamless pipes' lack of welds eliminates any potential weak areas and lowers the possibility of leaks or breakdowns. Additionally, it leads to enhanced flow characteristics, reducing pressure loss, and enabling effective fluid or gas transfer.

- Quality Control: To ensure that seamless pipes meet industry standards and requirements, stringent quality control procedures are used. To ensure their performance and integrity, they are put through a number of tests, including dimensional checks, mechanical testing, non-destructive testing, and corrosion resistance assessments.

In comparison to welded pipes, seamless pipes have a number of benefits, including as higher strength, increased dependability, and improved resistance to corrosion and high temperatures. However, because they require specialised production techniques, they may cost more to produce. Seamless pipes must be installed, handled, and maintained correctly in order to operate at their best and last a long time in a variety of applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Pipes' category

GST : 19ALVPP1192L1Z7

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free